Where To Start with and More

If you’re in the world of electronics manufacturing, you’re probably familiar with surface mount assembly. This process has become increasingly popular in Reno, Nevada, and around the world due to its efficiency and effectiveness. In this article, we’ll explore the top five facts about surface mount assembly in Reno, Nevada, and why it is crucial for your business.

1 Picture Gallery: Where To Start with and More

1. What is Surface Mount Assembly?

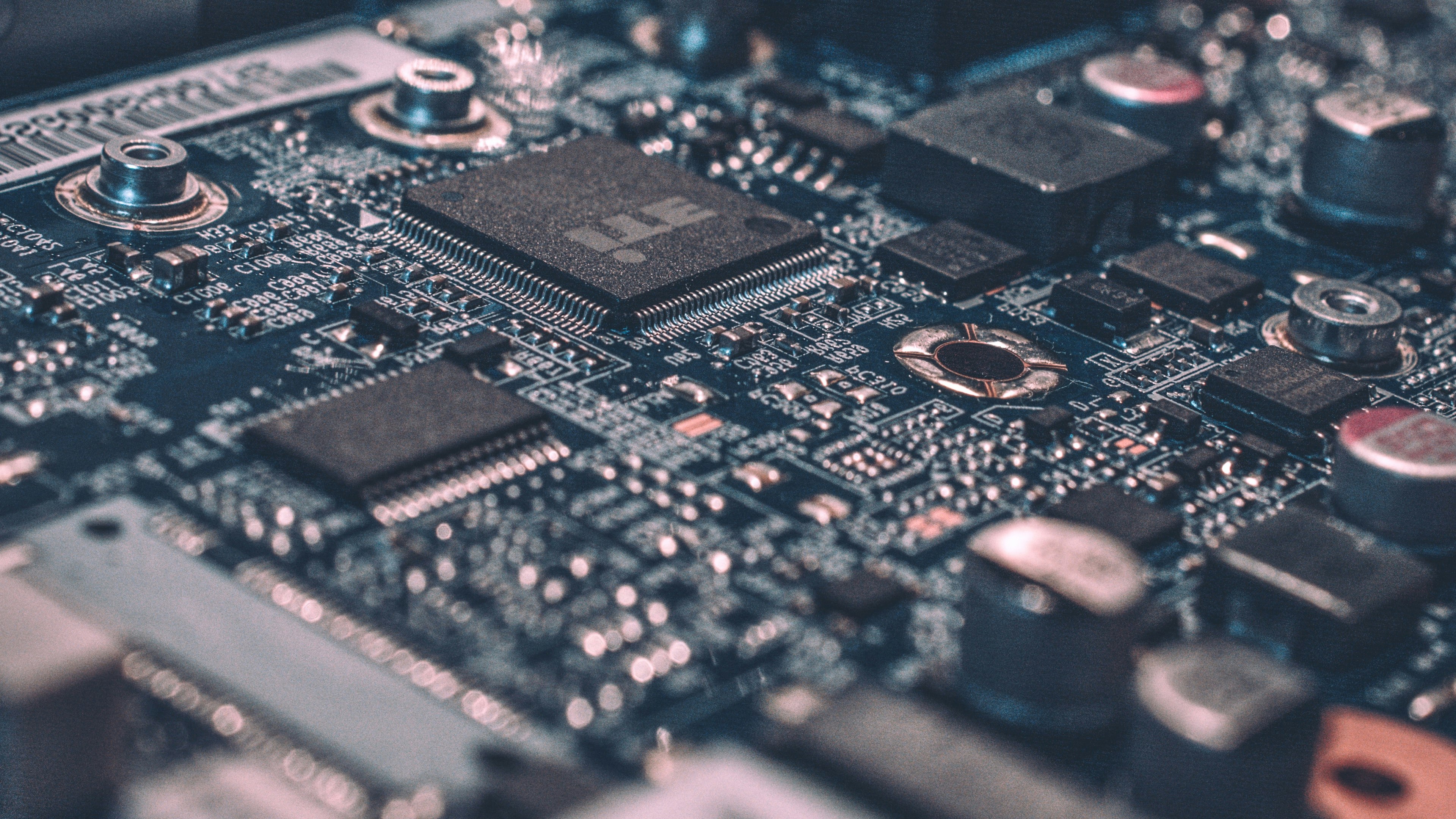

Surface mount assembly, also known as SMT assembly, is a method of electronic component placement on a printed circuit board (PCB). Unlike the traditional method of through-hole assembly, SMT assembly involves mounting components directly onto the board’s surface, resulting in smaller, lighter, and more cost-effective electronic devices. This technology has revolutionized the electronics industry and is widely used in Reno, Nevada, for various applications, including consumer electronics, automotive, aerospace, and medical equipment.

2. The Advantages of Surface Mount Assembly

Surface mount assembly offers numerous advantages over traditional through-hole assembly. Firstly, SMT components are smaller and more compact, allowing for greater functionality in smaller devices. This miniaturization is particularly important in industries where space is limited, such as mobile phones and wearables. Secondly, SMT assembly is highly automated, enabling faster production times and increased efficiency. Additionally, because SMT components are mounted on the surface, they have a shorter electrical path, leading to improved performance and signal integrity. Lastly, SMT assembly reduces manufacturing costs by eliminating the need for drilling holes and simplifying the overall production process.

3. The Role of Reno, Nevada in Surface Mount Assembly

Reno, Nevada, has emerged as a hub for surface mount assembly due to its strategic location and supportive business environment. The city’s proximity to major transportation networks and its access to a skilled workforce make it an ideal location for electronics manufacturing companies. Additionally, Reno’s favorable tax incentives and business-friendly policies have attracted numerous companies specializing in surface mount assembly. These factors, combined with the city’s robust infrastructure and strong supply chain, have positioned Reno as a leading destination for surface mount assembly in the United States.

4. The Importance of Quality Control in Surface Mount Assembly

As with any manufacturing process, maintaining high-quality standards is crucial in surface mount assembly. With the increasing complexity of electronic devices and the shrinking size of components, ensuring that each component is accurately placed and soldered is essential to prevent defects and malfunctions. Reno, Nevada, is known for its stringent quality control measures and adherence to industry standards. Companies in Reno invest heavily in advanced inspection equipment, including automated optical inspection (AOI) and X-ray inspection systems, to detect and address any potential issues during the assembly process. This commitment to quality control ensures that products manufactured in Reno meet the highest standards of reliability and performance.

5. The Future of Surface Mount Assembly in Reno, Nevada

The future of surface mount assembly in Reno, Nevada, looks promising. As technology continues to advance, the demand for smaller, more efficient electronic devices will only increase. Reno’s manufacturing industry is well-positioned to meet these demands, thanks to its established infrastructure, skilled workforce, and commitment to innovation. Furthermore, the city’s dedication to sustainability and eco-friendly practices aligns with the growing global concern for environmental impact. With ongoing advancements in surface mount assembly technology, Reno, Nevada, is poised to remain a leader in electronics manufacturing for years to come.

In conclusion, surface mount assembly plays a significant role in Reno, Nevada’s electronics manufacturing sector. Its advantages, including compactness, efficiency, and cost-effectiveness, have made it the preferred method for producing electronic devices. Reno’s strategic location, business-friendly environment, and commitment to quality control have established it as a thriving hub for surface mount assembly. As the industry continues to evolve, Reno’s manufacturing industry is poised for further growth and innovation in surface mount assembly. So, if you’re looking for high-quality electronic products, look no further than Reno, Nevada.

6 Facts About Everyone Thinks Are True

This post topic: Advertising & Marketing